Overview of Neoprene materials

The Neoprene material is a kind of synthetic rubber foam, there are two kinds of white and black. It is widely used in the manufacture of Neoprene materials, so everyone has an easy-to-understand name for it: SBR (Neoprene material).

Chemical composition: a polymer made of chloroprene as a monomer and emulsion polymerization.

Features and scope of application: good weather resistance, ozone aging resistance, self-extinguishing, good oil resistance, second only to nitrile rubber, excellent tensile strength, elongation, elasticity, but poor electrical insulation, storage stability, use The temperature is -35~130℃.

Features of Neoprene material

1. Protect the product from wear and tear;

2. The material is elastic, reducing the damage to the product caused by the impact;

3. Light and comfortable, it can also be used alone;

4. Fashionable design;

5. Long-term use without deformation;

6. Dustproof, anti-static, anti-scratch;

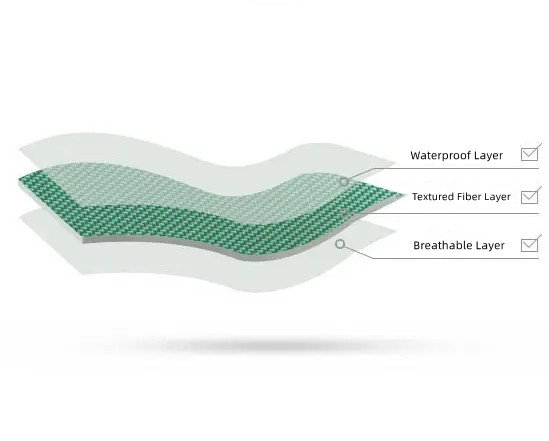

7. Waterproof and airtight, can be washed repeatedly.

Application of Neoprene material

In recent years, with the continuous reduction of cost and the vigorous promotion of many professional finished product manufacturers, it has become a new type of material that has been continuously expanded and expanded in application fields. After Neoprene is attached to fabrics of various colors or functions, such as: Jiaji cloth (T cloth), Lycra cloth (LYCRA), Mega cloth (N cloth), mercerized cloth, nylon (NYLON), OK cloth, imitation OK cloth, etc. .

Neoprene materials are widely used in: neoprene sports safety, neoprene medical care, neoprene outdoor sports, neoprene fitness products, posture corrector, diving suits, sports protective gear, body sculpting supplies, gifts, thermos cup sleeves, fishing pants, shoe materials and other fields.

The lamination of neoprene is different from general shoe material lamination. For different application fields, different lamination glues and lamination processes are required.

Neoprene Knee Support Neoprene Ankle Supp0rt Neoprene Wrist Support

Neoprene Tote Bag Neoprene Lunch Bag Neoprene Water Bottle Sleeve

Neoprene Wine Sleeve Neoprene Ankle&Wrist Weights Neoprene Posture Corrector

Classification of Neoprene materials

Common specifications and types of Neoprene (SBR CR) materials: NEOPRENE is a synthetic rubber foam, and neoprene materials with different physical properties can be foamed by adjusting the formula. The following materials are currently available:

CR series: 100% CR is suitable for surfing suits, wetsuits and other products

SW series: 15%CR 85%SBR suitable for cup sleeves, handbags, sports products

SB series: 30%CR 70%SBR Suitable for sports protective gear, gloves

SC series: 50%CR+50%SBR is suitable for fishing pants and vulcanized footwear products. In addition, according to the requirements of customers, neoprene materials suitable for special physical properties can be developed.

The production process of Neoprene material

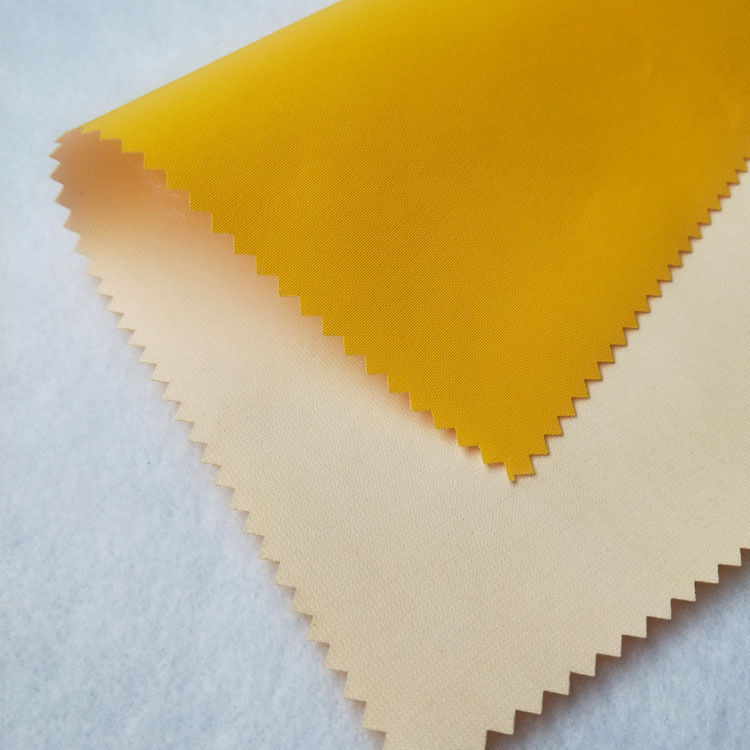

NEOPRENE is in units of pieces, usually 51*83 inches or 50*130 inches. Available in black and beige. The foam that has just been foamed becomes a sponge bed, with a thickness of 18mm~45mm, and its upper and lower surfaces are relatively smooth, called smooth skin, also known as smooth skin. The texture of embossing includes coarse embossing, fine embossing, T-shaped texture, diamond-shaped texture, etc. Coarse embossing is called shark skin, and fine embossing becomes fine skin. The split pieces after splitting the neoprene sponge bed become open cell, usually paste on this side. Neoprene can be processed into split pieces of 1-45mm thickness as required. Fabrics of various materials, such as LYCRA (Lycra), JERSEY (Jiaji cloth), TERRY (mercerized cloth), NYLON (nylon), POLYESTER, etc., can be attached to the processed NEOPRENE split piece. The laminated fabric can be dyed in various colors. The lamination process is divided into ordinary lamination and solvent-resistant (toluene-resistant, etc.) lamination. The ordinary lamination is suitable for sports protective gear, handbag gifts, etc., and solvent-resistant lamination is used for diving. Apparel, gloves and other products that need to be used in a solvent environment.

Physical properties of Neoprene (SBR CR Neoprene material) material 1. Physical properties of Neoprene (Neoprene material): Neoprene rubber has good flex resistance. The results of the cover rubber test of the domestic heat-resistant conveyor belt are: the natural rubber compound formula that produces the same degree of cracking is 399,000 times, the 50% natural rubber and 50% neoprene rubber compound formula is 790,000 times, and 100% The neoprene compound formula is 882,000 cycles. Therefore, the product has a good memory ability and can be folded at will, without deformation and without leaving a folded mark. The rubber has good shockproof performance, adhesion and sealing performance, and is widely used in the manufacture of sealing parts and shockproof parts in household appliances, mobile phone covers, thermos bottle covers, and footwear manufacturing. Therefore, the product has good softness and slip resistance. The flexibility can effectively set off the user’s wrist and reduce wrist strain. The anti-slip properties prevent the mouse pad from moving, allowing users to operate the mouse robustly. 2. Chemical properties of Neoprene (Neoprene material): The double bonds and chlorine atoms in the neoprene structure are not active enough to cause chemical reactions. Therefore, it is generally used in products with high chemical resistance requirements, which also makes the products less prone to aging and cracking. The rubber has a stable structure, is non-toxic and harmless, and is widely used in the manufacture of Neoprene materials, sports protection products and body sculpting products. The rubber has good flame retardancy, is safe and reliable to use, and is mostly used for flame retardant cables, flame retardant hoses, flame retardant conveyor belts, bridge supports and other flame retardant plastic parts. The rubber has good water resistance and oil resistance. It is used in oil pipelines and conveyor belts. The above characteristics also make the product durable and durable, such as repeated washing, anti-deformation, not easy to age and crack.

Because it is a synthetic modified rubber, its price is about 20% higher than that of natural rubber. 3. Adaptability: Adapt to various climates, the minimum cold resistance is -40 °C, the maximum heat resistance is 150 °C, the minimum cold resistance of general rubber is -20 °C, and the maximum heat resistance is 100 °C. Widely used in the manufacture of cable jackets, rubber hoses, construction sealing strips and other fields

How to choose diving material

1. First, determine the product category to be produced, and select different Neoprene materials such as CR, SCR, SBR, etc. in a targeted manner.

2. To determine the thickness of the submersible material, generally use a vernier caliper to measure (preferably with a professional thickness gauge). Due to the soft characteristics of the submersible material, do not press hard when measuring, and the vernier caliper can move freely. The quality and feel of the finished products made of materials of different thicknesses will also be different. Products made of thicker materials are more durable and have better shock and drop resistance.

3. Determine the fabric that the Neoprene material needs to be attached to, there will be more options, such as Lycra, OK fabric, nylon fabric, polyester fabric, terry cloth, edge fabric, Jiaji cloth, mercerized cloth, etc. The skin feel and texture brought by different fabrics are also different, and the composite fabric can be determined according to the actual market demand. Of course, you can also choose fabrics and linings to use different fabrics to fit.

4. Determine the color of the Neoprene material, usually there are two types of Neoprene material: black and white. The more commonly used black Neoprene material. White Neoprene material can also be selected according to actual market demand.

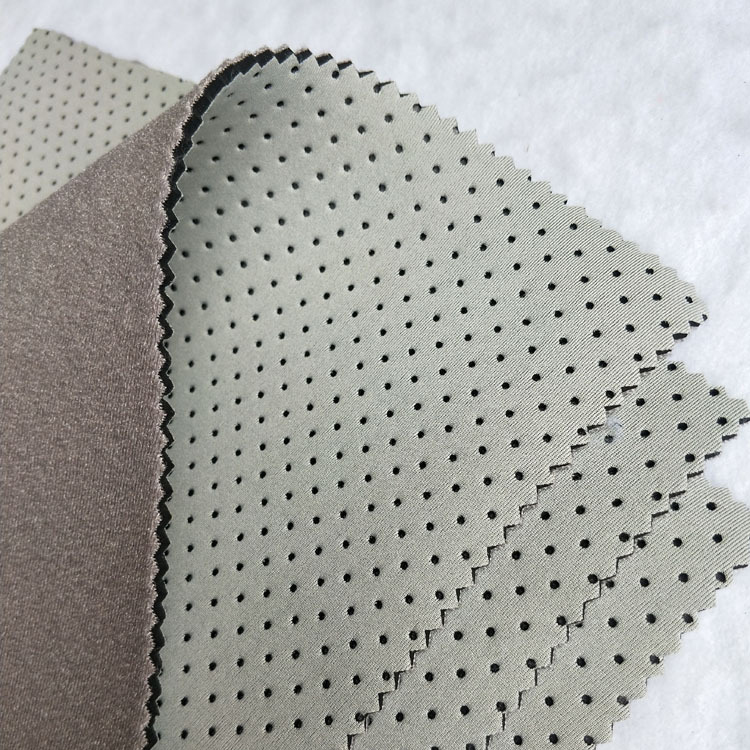

5. Determine the characteristics of the Neoprene material. The Neoprene material can usually be perforated or non-perforated. The perforated Neoprene material has better air permeability. If it is a fitness product that requires sweating, it is better to choose a non-perforated Neoprene material.

6. Determine the process, different processes are suitable for different products. For example, you can choose embossed Neoprene material, which will have a non-slip function.

7. Whether you need solvent-resistant lamination during lamination depends on where your product is used. If it is a product that goes to sea, such as diving suits, diving gloves, etc., it will need solvent-resistant lamination. Ordinary gifts, protective gear and other ordinary fit can be.

8. Thickness and length error: The thickness error is generally around plus or minus 10%. If the thickness is 3mm, the actual thickness is between 2.7-3.3mm. The minimum error is about plus or minus 0.2mm. The maximum error is plus or minus 0.5mm. The length error is about plus or minus 5%, which is usually longer and wider.

The concentration of Neoprene materials in China

As we all know, Dongguan City, Guangdong Province, China is known as “the world’s factory”. Dongguan City is full of raw materials for all walks of life. For example, Dalang Town, Dongguan City is known as the world’s woolen center. Similarly, Liaobu Town, Dongguan City It is the concentration of raw materials for Neoprene materials in China. Therefore, Liaobu Town, Dongguan City brings together the source manufacturers of Neoprene materials from all walks of life. The advantages of the supply chain and the manufacturing capacity of the source factory have brought us super core competitiveness, and also brought our customers the best guarantee in terms of price, quality, delivery and other aspects.

Post time: Jul-28-2022